LAB. MET – The first in Europe to be accredited according to the ASTM E975 method

EUROPEAN LAB.MET RECORD

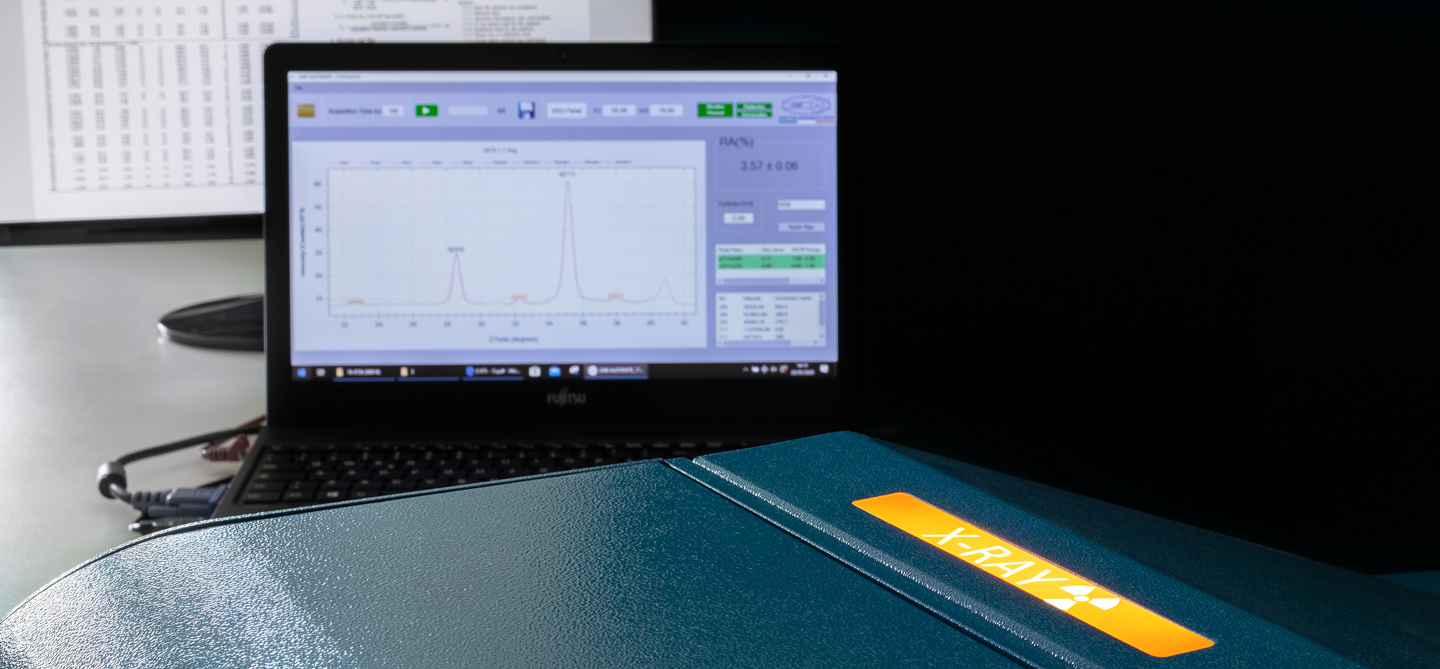

X-ray diffractometry is the leading method for determining residual austenite content, and LAB.MET is the first in Italy and Europe to have achieved accreditation of the method.

A REVOLUTION IN THE WORLD OF ANALYSIS

The increase in the carbon content leads to a lowering of the MS (martensite start) and MF (martensite finish) temperatures, favouring an incomplete transformation of austenite into martensite during hardening. The high content of certain alloying elements can also lead to a stabilisation of austenite and a lowering of MS and MF.

The presence of a certain fraction of residual austenite at the end of the hardening treatment can be a target to be reached to impart toughness, but in most cases it represents a problem since its metastable nature can lead to its transformation at room temperature following modest energy contributions (in the form of heat or mechanical stresses). This delayed transformation of austenite into ferrite/martensite is accompanied by a 4% increase in volume, which can lead to dimensional changes with loss of profile or mating tolerances and the onset of deleterious stress states capable of compromising the life of a component.

Traditionally, the quantification of the content of a material in terms of residual austenite is through visual metallographic examination, associated with image analysis systems or comparison tables. These methods, in addition to not constituting immediate screening, are strongly influenced by the preparation and judgement of the person observing the sample under the light microscope and are often inapplicable, non-repeatable and limited to samples with austenite contents greater than 10%.

These problems, which have been known for decades, make the use of X-ray diffractometry compulsory, which is able to cope with the important limitations of classical methods and leads very quickly to accurate and repeatable results. The method applied is that of ASTM E975 ‘Standard practice for X-ray determination of retained austenite in steel with near random crystallographic orientation‘ and is based on the comparison of the integrated intensities of the diffraction peaks of austenite and ferrite.

Thanks to this analysis, it is possible to obtain the volumetric fraction of residual austenite within minutes by comparing the areas subtended by the various peaks of the diffractogram obtained. Furthermore, this technique provides, under certain conditions, the opportunity to carry out investigations directly on the external surface of artefacts and plan analyses at various depths for the verification of massive and/or surface treatments.

Obtaining these results certainly requires the use of appropriate machinery, and LAB.MET, a long-standing leader in innovation, has been able to prove its active role in this panorama as well by equipping itself with state-of-the-art instruments that to date make it the only laboratory in Europe to have achieved method accreditation according to ISO 17025.