WELDING

In consultation with all departments of the Laboratory, preparatory activities for the qualification of manual and automatic welding procedures ( WPS Welding Procedure Specification and WPQR Welding Procedure Qualification Record), manual and automatic welding proceduresWPS Brazing Procedure Specification and WPQR (Welding Procedure Qualification Record brazing procedures (WPS Brazing Procedure Specification and WPQR Welding Procedure Qualification Record), brazing procedures (WPS Brazing Procedure Specification and WPQ Brazing Procedure Qualification Record), and welding operators WQ Welder Approval Test Certificate – Manual Welder Certificate according to UNI EN ISO 9606 – Welding Operator Certificate according to UNI EN ISO 14732 – BQ Brazer Certificate according to UNI EN ISO 13585)

All tests for qualification activities are carried out in-house:

- Non-Destructive Examination of the Joint

- Tensile, resilience and bending mechanical tests with internal processing of all specimens

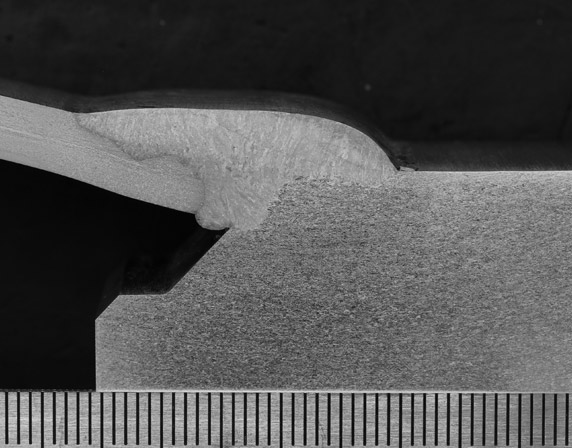

- Macrographic investigations and hardness seams

- Evaluation of the WPS soldering and BPS brazing procedure

Welding

The application of European standards such as UNI EN ISO 15614, UNI EN ISO 15613 for various sectors such as construction (EN 1090 and ISO 3834), railways (EN 15085), shipbuilding, PEDs, etc. or international standards (e.g. ASME Code and AWS) leads to the qualification of welding procedures such as

- 111 Arc welding with coated electrodes

- 114 Flux-cored wire welding (without protective gas)

- 121 Submerged-arc welding with a single electrode wire

- 125 Submerged-arc welding with flux-cored wire

- 131 Inert gas welding with fusible electrode wire (MIG)

- 135 Active gas welding with fusible electrode wire (MAG)

- 136 Active gas welding with flux cored electrode wire

- 141 Inert gas welding with tungsten electrode (GTAW)

- 15 Plasma welding

- 311 Oxyacetylene Welding

The department’s services are completed by inspection and control activities in the field performed by qualified professionals for the monitoring of job orders characterised by short/medium/long-term control plans: monitoring of welds and the progress of the job order, monitoring of the status of controls and the personnel assigned to their execution.

J. Srebernic Street 10/12

34077 Ronchi dei Legionari GO

Italy

VAT 00547070318

LAB.MET SRL

Venezia Street 22

33085 Maniago PN

Italy

VAT 01581810932

J. Srebernic Steet 14

34077 Ronchi dei Legionari GO

Italy

P. IVA 01156680314

SUZHOU METAL SERVICES CO. LTD.

Yinsheng Road, No.125

215126 ShengPu Town Suzhou Jiangsu

China